Robotic engineering is shaping industries in ways many people don’t even realize. In Alabama, cutting-edge robotics are quietly transforming manufacturing, healthcare, and even nuclear safety. The state’s robotics engineering companies are developing technology that enhances efficiency, precision, and safety across multiple sectors.

Automotive Assembly Lines Accelerated by Ingenious Robotic Precision

Alabama has become a major hub for the automotive industry, and robotics play a key role in keeping production fast and efficient. Robotic systems handle intricate tasks such as welding, painting, and assembling vehicle components with unmatched accuracy. This automation not only speeds up production but also ensures consistent quality, reducing defects and waste. A robotics engineering company in Alabama is likely to have a hand in designing custom solutions for car manufacturers, helping them meet the increasing demand for vehicles.

Beyond speed and efficiency, robotic automation enhances worker safety in automotive plants. Heavy lifting, repetitive tasks, and exposure to hazardous materials are some of the risks mitigated by robotics. By automating dangerous processes, Alabama robotics engineering companies help protect workers while keeping factories running at peak performance. With vehicle demand on the rise, these robotic solutions will continue to shape the future of car manufacturing in Alabama and beyond.

Aerospace Innovations Driven by Alabama’s Robotic Engineering Breakthroughs

The aerospace industry demands extreme precision, and robotic engineering is at the core of many breakthroughs in Alabama. Advanced robotics assist in building aircraft, spacecraft, and even satellite components, ensuring each part meets the industry’s strict tolerances. Robotic arms can maneuver in ways human hands cannot, allowing them to perform delicate assembly work with precision that prevents errors and structural weaknesses.

In addition to manufacturing, robotic systems are being developed to inspect and maintain aerospace components. Drones and robotic crawlers can examine aircraft surfaces for defects, reducing maintenance time and increasing safety. Alabama robotics engineering companies are also involved in developing autonomous systems for space exploration, where robots perform tasks in environments too dangerous or inaccessible for humans. As space missions and aircraft production continue to advance, Alabama’s role in aerospace robotics will only grow.

Nuclear Safety Elevated by Specialized Robotic Interventions

The nuclear sector relies on robotics to handle tasks that would be too risky for human workers. From monitoring radiation levels to performing maintenance in high-risk areas, robots have become essential in ensuring the safety of nuclear facilities. A robotics engineering company in Alabama may develop robotic arms, remotely operated vehicles, or AI-driven monitoring systems designed to withstand extreme conditions.

One of the most important contributions of robotics in this field is disaster response. In the event of a nuclear accident, robotic systems can enter contaminated areas to assess damage, seal leaks, or remove hazardous materials without putting human lives at risk. These advanced technologies enhance safety protocols and help prevent potential disasters. Alabama’s expertise in robotics engineering is helping redefine nuclear safety on both national and global scales.

Medical Advancements Enhanced Through Robotic Surgical Precision

Robotic-assisted surgery has revolutionized modern medicine, providing doctors with tools that increase precision and reduce recovery times for patients. Alabama robotics engineering companies contribute to this evolution by designing robotic systems that assist in delicate procedures such as neurosurgery, orthopedic surgeries, and minimally invasive operations. These robotic tools allow surgeons to perform complex procedures with greater accuracy, leading to better patient outcomes.

Beyond surgery, robots are also transforming patient care in hospitals and rehabilitation centers. Automated assistants help transport supplies, dispense medications, and even assist patients with mobility exercises. This not only reduces the workload on medical staff but also improves efficiency in healthcare facilities. With continuous advancements in robotics engineering, Alabama remains at the forefront of innovation in the medical field, developing technology that enhances both surgical precision and overall patient care.

Robotics Quietly Revolutionizing Research and Development Processes

Scientific research depends on accuracy and efficiency, and robotics are playing a growing role in laboratory settings. From automating chemical experiments to handling hazardous materials, robotics ensure that researchers can conduct experiments with minimal risk and maximum precision. A robotics engineering company in Alabama might develop automated lab equipment that can mix compounds, test samples, and collect data with consistent accuracy.

One of the most exciting developments is the use of AI-powered robots to accelerate discoveries in pharmaceuticals, materials science, and biotechnology. These robotic systems can run thousands of tests in a fraction of the time it would take a human researcher, leading to faster breakthroughs. As technology evolves, Alabama robotics engineering companies will continue to shape the future of research, making innovation faster, safer, and more reliable.

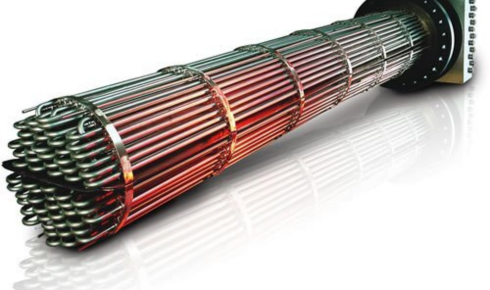

Steel Production Boosted Through Intelligent Robotic Automation

Steel manufacturing is another industry where robotics are making a significant impact. The process of smelting, forging, and cutting steel requires extreme heat and precision, making it an ideal field for robotic intervention. Automated robotic systems help with tasks such as welding, material handling, and quality inspection, improving both efficiency and worker safety.

One of the biggest advantages of robotic automation in steel production is consistency. Unlike human workers, robots do not experience fatigue, allowing them to maintain high-quality output across long production runs. Alabama robotics engineering companies are designing systems that help steel manufacturers meet growing demand while minimizing errors and waste. By integrating intelligent automation, steel production in Alabama is becoming faster, safer, and more cost-effective, ensuring the industry remains competitive in the modern era.